| Body |

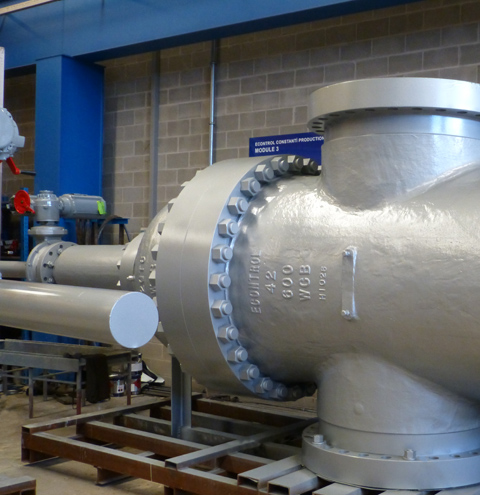

ASTM A216, A105, A350, A182, A351, A352, A890, A995, C95300, C95800, MONEL, INCONEL. Please enquiry for different material configurations |

| Trim |

ASTM A216, A105, A350, A182, A351, A352, A890, A995, C95300, C95800, MONEL, INCONEL. Please enquiry for different material configurations |

| Seat(s) |

PTFE, NYLON, PEEK, NBR, KELF, ENP (Electroless nickel plating), HC (Hard chrome), TC (Tungsted carbide). Please enquiry for different material configurations |

| Sealing |

BUNA-N, EPDM, VITON, Flexible graphite, FKM, HNBR, Nitrile, Neoprene. Please enquiry for different material configurations |